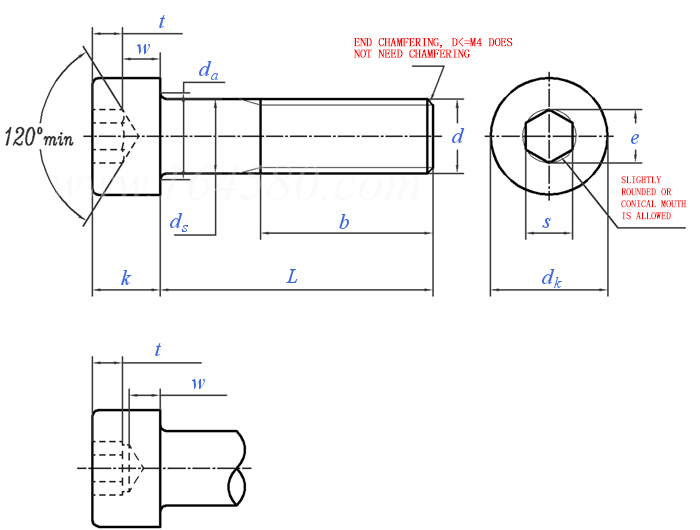

| Gewënngréisst | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | ||||

| d | |||||||||||||||||||

| P | Gewënnschréi | grob | 0,3 | 0,35 | 0,4 | 0,45 | 0,5 | 0,7 | 0,8 | 1 | 1,25 | 1.5 | 1,75 | 2 | 2 | 2,5 | 2,5 | ||

| fein1 | - | - | - | - | - | - | - | - | 1 | 1,25 | 1,25 | 1.5 | 1.5 | 1.5 | 1.5 | ||||

| fein2 | - | - | - | - | - | - | - | - | - | 1 | 1.5 | - | - | 2 | 2 | ||||

| dk | ronne Kapp | maximal | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8,5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | ||

| geriffelte Kapp | maximal | 2,74 | 3.14 | 3,98 | 4,68 | 5,68 | 7.22 | 8,72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |||

| Minutten | 2,46 | 2,86 | 3,62 | 4.32 | 5.32 | 6,78 | 8.28 | 9,78 | 12,73 | 15,73 | 17,73 | 20,67 | 23,67 | 26,67 | 29,67 | ||||

| da | maximal | 1.8 | 2 | 2.6 | 3.1 | 3.6 | 4.7 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17,7 | 20.2 | 22.4 | |||

| ds | maximal | 1.4 | 1.6 | 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |||

| Minutten | 1,26 | 1,46 | 1,86 | 2,36 | 2,86 | 3,82 | 4,82 | 5,82 | 7,78 | 9,78 | 11,73 | 13,73 | 15,73 | 17,73 | 19,67 | ||||

| e | Minutten | 1.5 | 1,73 | 1,73 | 2.3 | 2,87 | 3,44 | 4,58 | 5,72 | 6,86 | 9.15 | 11.43 | 13,72 | 16 | 16 | 19.44 | |||

| k | Minutten | 1.4 | 1.6 | 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |||

| Minutten | 1,26 | 1,46 | 1,86 | 2,36 | 2,86 | 3,82 | 4,82 | 5.7 | 7,64 | 9,64 | 11,57 | 13,57 | 15,57 | 17,57 | 19.48 | ||||

| s | nominell | 1.3 | 1.5 | 1.5 | 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 | |||

| Minutten | 1,32 | 1,52 | 1,52 | 2.02 | 2,52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | ||||

| maximal | 1,36 | 1,56 | 1,56 | 2.06 | 2,58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | ||||

| t | Minutten | 0,6 | 0,7 | 1 | 1.1 | 1.3 | 2 | 2,5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||

| w | Minutten | 0,5 | 0,55 | 0,55 | 0,85 | 1.15 | 1.4 | 1.9 | 2.3 | 3 | 4 | 4.8 | 5.8 | 6.8 | 7.8 | 8.6 | |||

| 螺纹尺寸 | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | |||||

| d | |||||||||||||||||||

| P | Gewënnschréi | grob | 2,5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 | |||

| Fein1 | 1.5 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |||||

| Fein2 | 2 | - | - | - | - | - | - | - | - | - | - | - | - | - | |||||

| dk | ronne Kapp | maximal | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 | |||

| geriffelte Kapp | maximal | 33,39 | 36,39 | 40,39 | 45,39 | 50,39 | 54,46 | 63,46 | 72,46 | 84,54 | 96,54 | 108,54 | 120,54 | 135,63 | 150,63 | ||||

| Minutten | 32,61 | 35,61 | 39,61 | 44,61 | 49,61 | 53,54 | 62,54 | 71,54 | 83,46 | 95,46 | 107,46 | 119,46 | 134,37 | 149,37 | |||||

| da | maximal | 24.4 | 26.4 | 30.4 | 33,4 | 36,4 | 39,4 | 45,5 | 52,6 | 63 | 71 | 79 | 87 | 97 | 107 | ||||

| ds | maximal | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 | ||||

| Minutten | 21,67 | 23,67 | 26,67 | 29,67 | 32,61 | 35,61 | 41,61 | 47,61 | 55,54 | 63,54 | 71,54 | 79,54 | 89,46 | 99,46 | |||||

| e | Minutten | 19.44 | 21,73 | 21,73 | 25.15 | 27.43 | 30,85 | 36,57 | 41.13 | 46,83 | 52,53 | 62,81 | 74,21 | 85,61 | 97,04 | ||||

| k | maximal | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 | ||||

| Minutten | 21.48 | 23.48 | 26,48 | 29,48 | 32,38 | 35,38 | 41,38 | 47,38 | 55,26 | 63,26 | 71,26 | 79,26 | 89,13 | 99,13 | |||||

| s | nominell | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 | ||||

| Minutten | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36,08 | 41.08 | 46.08 | 55,1 | 65,1 | 75,1 | 85,12 | |||||

| maximal | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32,33 | 36,33 | 41,33 | 46,33 | 55,4 | 65,4 | 75,4 | 85,47 | |||||

| t | Minutten | 11 | 12 | 13,5 | 15,5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 | ||||

| w | Minutten | 9.4 | 10.4 | 11.9 | 13.1 | 13,5 | 15.3 | 16.3 | 17,5 | 19 | 22 | 25 | 27 | 32 | 34 | ||||

PRODUKTDETAILER:

Allgemeng aus Edelstol Drot SUS304 hiergestallt. Et ginn zwou Zorte vun Edelstol Sechskantschrauwen um Maart: geriffelte Kapp a geriffelte Kapp. Edelstol Sechskantschrauwen mat Innenschrauben kënnen am Allgemengen net vun der Uewerfläch ënnerscheedlech gemaach ginn, awer et kann um Produktiounsprozess vun der Schrauf beurteelt ginn (Branchenerfahrung, nëmme als Referenz): Am Allgemengen kann de Kapp vun Edelstol Sechskantschrauwen mat Innenschrauben e riichte Kroller-Prozess hunn a kënnen als authentesch SUS304 Produktioun vu Schrauwen beurteelt ginn. Edelstol Sechskantschrauwen ouni Kryptonit um Kapp kënnen als e bësse mannerwäertegt Material oder Produkter mat engem méi niddrege Nickelgehalt ugesi ginn. Déi spezifesch Analyse hänkt awer vum Bericht vun der Qualitéitsinspektiounseenheet of.

Eng Edelstahl-Sechseck-Inset-Schraube ass eng Zort Lachschraube, déi allgemeng a Maschinnewierksgeschir, chemeschen Ausrüstung, Waasserpompelen, Schëffer, Kraaftwierksausrüstung an anere Plazen agesat gëtt. Eng Vollzänn-Edelstahl-Sechseck-Inset-Schraube gëtt méi dacks benotzt, an eng Hallefzänn-Edelstahl-Sechseck-Inset-Schraube gëtt am Inland méi dacks an Exportausrüstung agesat. D'Material gëtt an zwou Zorten opgedeelt: SUS304 Edelstahl-Sechseck-Schraube, Beschreiwung vun der Festigkeitsklass - A2-70. Schrauben aus Sechseck-Inset, SUS316 Edelstahl, Beschreiwung vun der Festigkeitsklass - A4-70.

FABRIEK AN VERPACKUNG:

MIR SINN OP DER BEVESTIGUNGSMAART: